Motorhome Camper

Automotive

Motorhome Camper

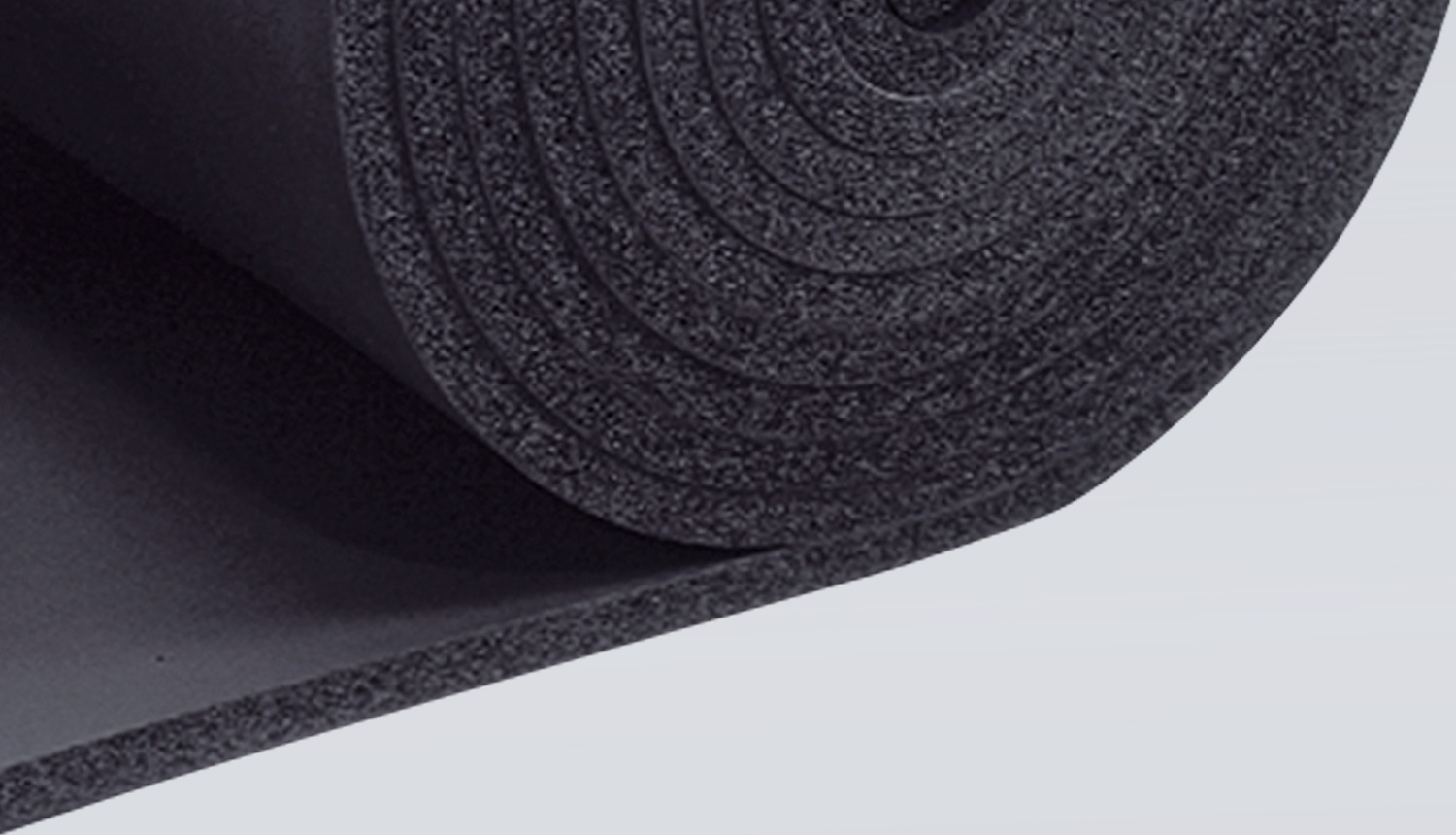

Mattress and seat foams

Individual mattresses and foam padding for motorhomes.

Sound insulation Thermal insulation

Coach insulation and insulation

Anti-slip mats and foam order systems

Vibra? foam anti-slip mats and organisation systems

Frequently asked questions (FAQ)

The fire behaviour of building materials is assessed according to their fire and smoke behaviour and classified with a BKZ (fire code number) according to VKF (Association of Cantonal Fire Insurance Companies). These are determined by standardised tests.

The fire index is made up of the degree of flammability ( 1-6 ) and the smoke level (.1-.3). Highly flammable and rapidly burning materials (flammability grades 1-2 ) are not permitted as building materials in fire protection.

Fire classification numbers

3 highly flammable

4 medium combustible

5 hardly inflammable

5 ( 200? ) hardly inflammable at 200?C

6 not flammable

Smoke level

.1 strong smoke formation

.2 moderate smoke generation

.3 low smoke generation

Example: Fire code number 5.2 = hardly combustible, medium smoke formation

Acoustic foams which have the fire protection class FMVSS 302 are mainly used in vehicle and machine construction. By adding flame retardant to the foam, the speed of flame propagation in case of fire is reduced. (4 inch/minute)

The test method introduced in the USA as the Federal Motor Vehicle Safety Standard (FMVSS 302) is used by most of the world's automobile manufacturers.

Generally speaking, structure-borne sound is sound that propagates in solid bodies such as steel, concrete, etc. through vibration.

Structure-borne sound is sound that propagates in a solid body. When sound is transmitted to a solid body, the latter is set into vibration by the sound transmission. Thereby the sound propagates e.g. over thin-walled metal sheets or over the masonry.

Sound attenuation can be understood as the prevention of sound spreading through the absorption of airborne sound. The sound energy is converted into inaudible oscillation waves during sound absorption and as a result the reflection at a boundary surface is reduced. The acoustics within the room are improved and the noise is reduced.

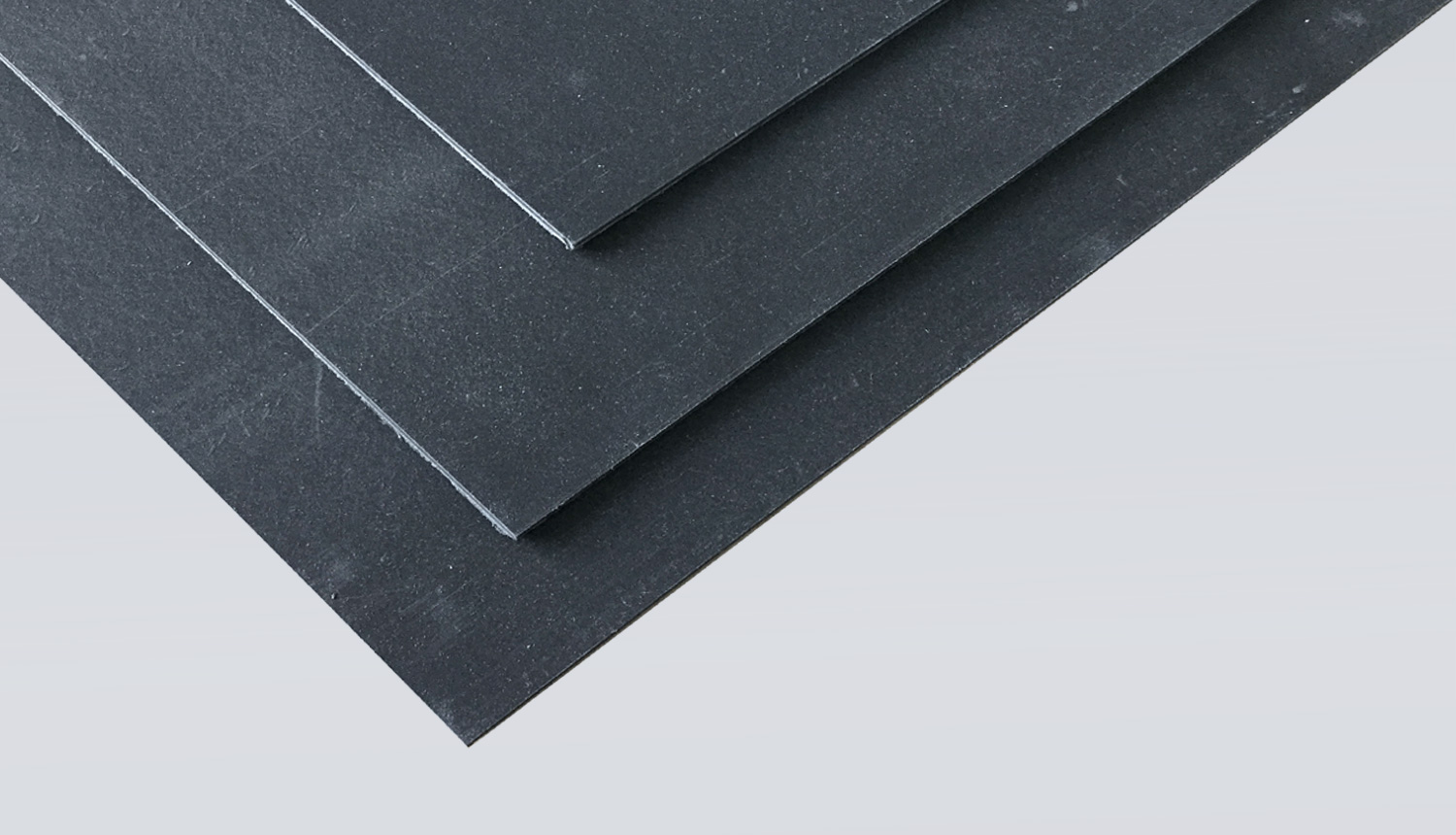

Heavy foils are heavy, viscoelastic foils based on plastic or bitumen, which are mainly used to improve the airborne sound insulation (anti-drumming) of thin-walled sheet metal constructions or lightweight construction walls as well as for structure-borne sound insulation (absorption).

The heavy foils from the Vibraplast range have various fire protection certificates such as the fire classification number (BKZ) 5.2 or 5.3 according to VKF / UL 94 / EN 45525 / DIN 4102-1 B2

Through the principle of mass increase (weighting), heavy foils for sound insulation bring about a decisive improvement in the (airborne) sound insulation properties of lightweight construction elements made of wood, wood-based materials, plasterboard or thin sheets of steel, aluminium or plastic. Weighting means full-surface connection (gluing) with the light elements. This increases their weight. Thickness and bending stiffness, however, are only minimally increased. Thereby high sound insulation values can be achieved with slim constructions.

In addition, due to their high internal damping capacity, heavy foils have an excellent effect as anti-drumming material, e.g. for thin-walled sheet metal constructions (anti-drumming effect).

The basic rule when using bituminous or plastic heavy foils as anti-drumming when bonding sheeting is: The sheet thickness x 2 gives the thickness of the anti-drumming foil, 2/3 of which is applied to the surface.

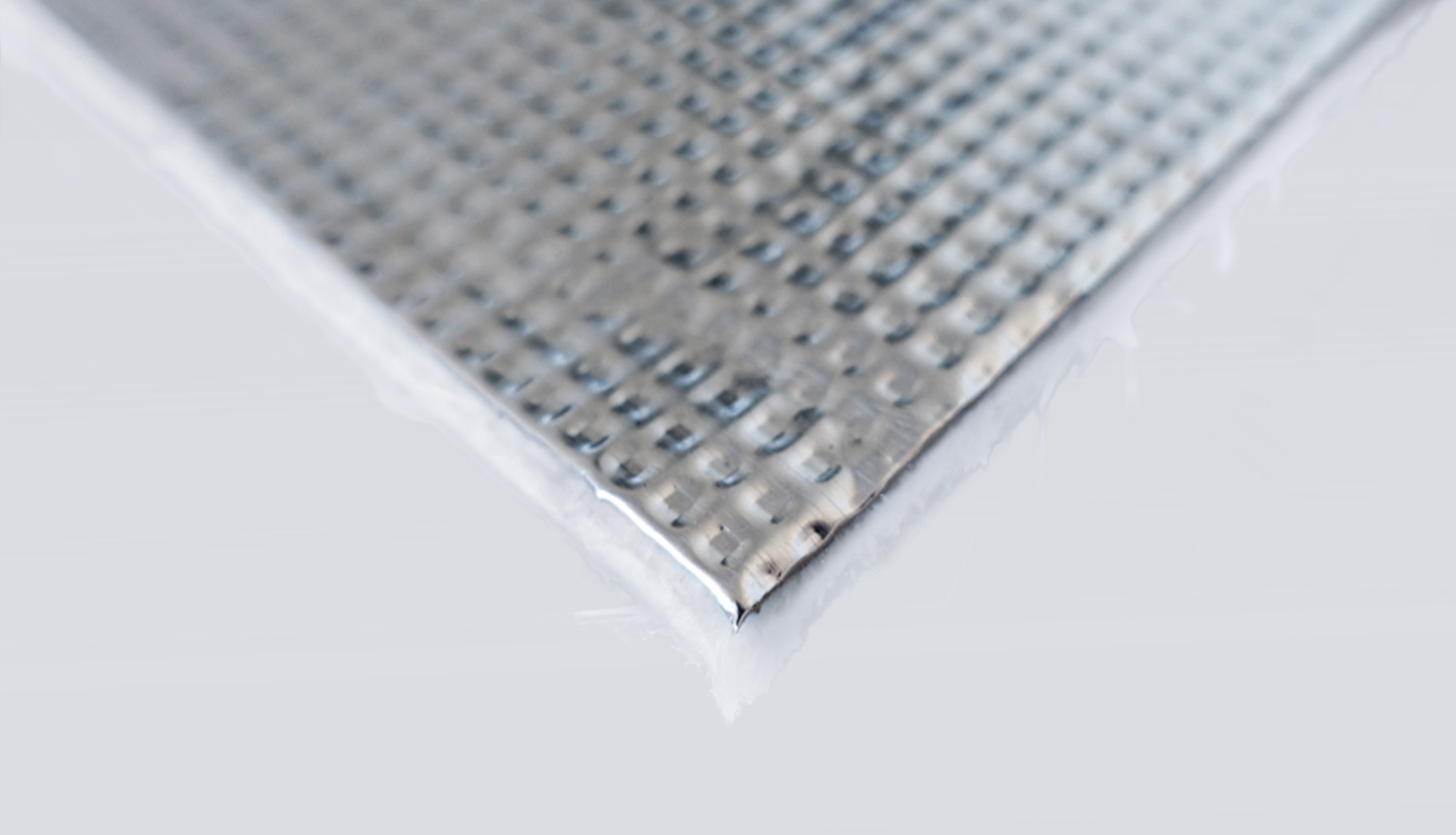

Tedrodem? Kobination sound insulation mat has the BKZ 5.2 (hardly combustible with medium smoke formation)

For vertical (wall) and overhead (ceiling) applications of heavy foils, which place very high demands on the tensile or shear strength of the bond, we generally recommend increasing the strength of the bond by applying an adhesive film to the surface of the construction material to be weighted down (contact adhesive, adhesive spray). Mechanical safety fastenings (metal strips, wooden slats, wide-head nails) can also be provided for this purpose.