drum kit

Online consulting!

Eliminating K?rpferschall when playing drums.

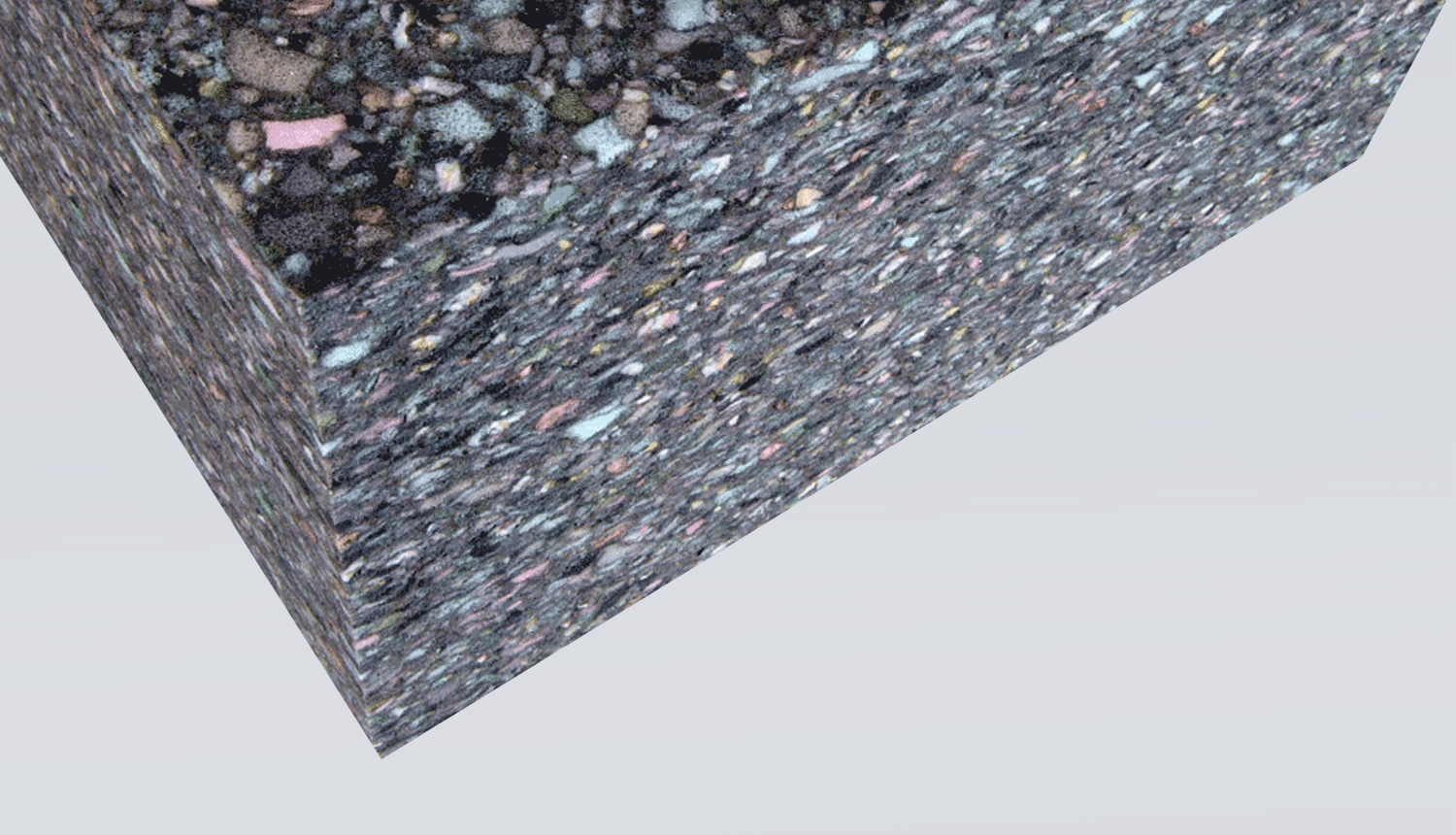

When playing drums, the sound development mainly leads to low frequencies and this also causes body vibrations. The vibrations are transmitted to floors and adjacent walls and the sound is also transmitted to adjacent rooms and parts of buildings. In order to prevent this unpleasant sound development, the drums should be decoupled from the other structures. A good solution is to build a platform with suitable sound absorbers. For low frequencies which occur when playing drums, the composite foam recycling foam is the right solution.

When planning the construction of a pedestal, it is important to ensure that the pedestal does not have direct contact with the walls. The first step in planning is to choose the right location. Under no circumstances should the platform have direct contact with the walls. For the lining, it is best to use a composite foam of approx. 60 mm thickness and 140 kg/m3 density. Make sure that the entire surface of the platform is lined with composite foam. In order to avoid so-called sound bridges, the installation must be carried out over the entire surface, there must be no gaps. A load-bearing layer in the form of a chipboard can now be applied to the composite foam and bonded to the composite foam. In this way we obtain a floating floor which serves as a structure-borne sound decoupling. The pedestal should not be screwed into the ground, because otherwise sound bridges (sound bridges in buildings transmit unwanted sound) could be created again and the elasticity of the "floating floor" would be impaired.

Room acoustic optimizations in the drum practice room.

In order to improve the room acoustics in the drum practice room, a wide range of products from our Silphon sound insulation range are available.

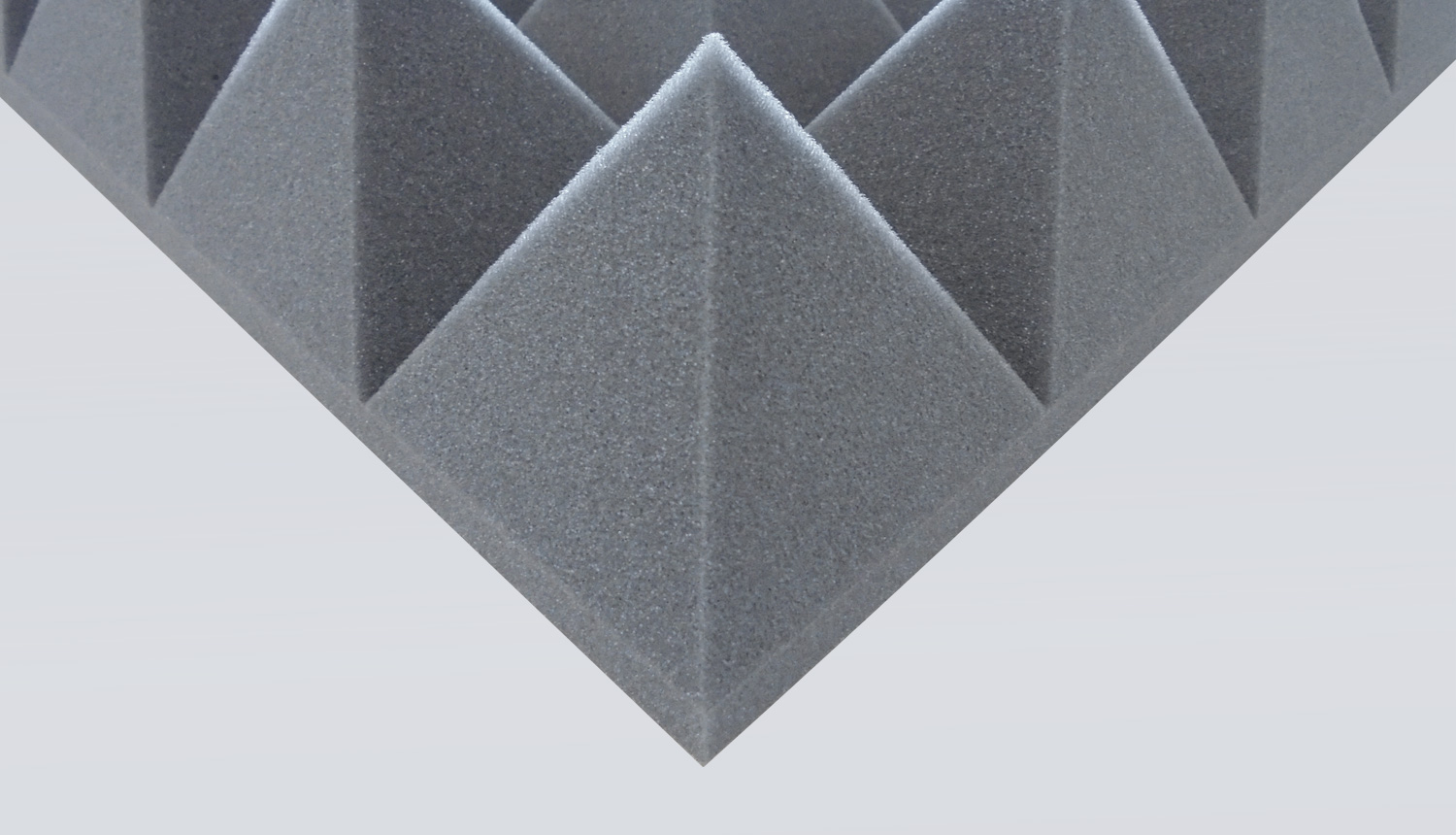

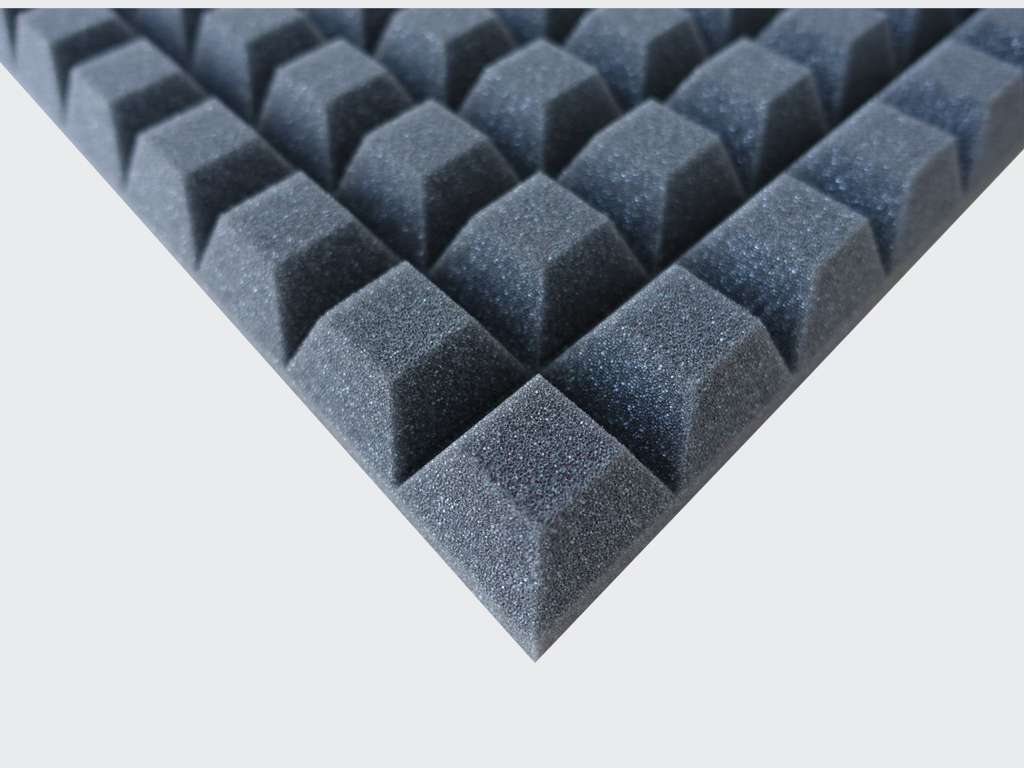

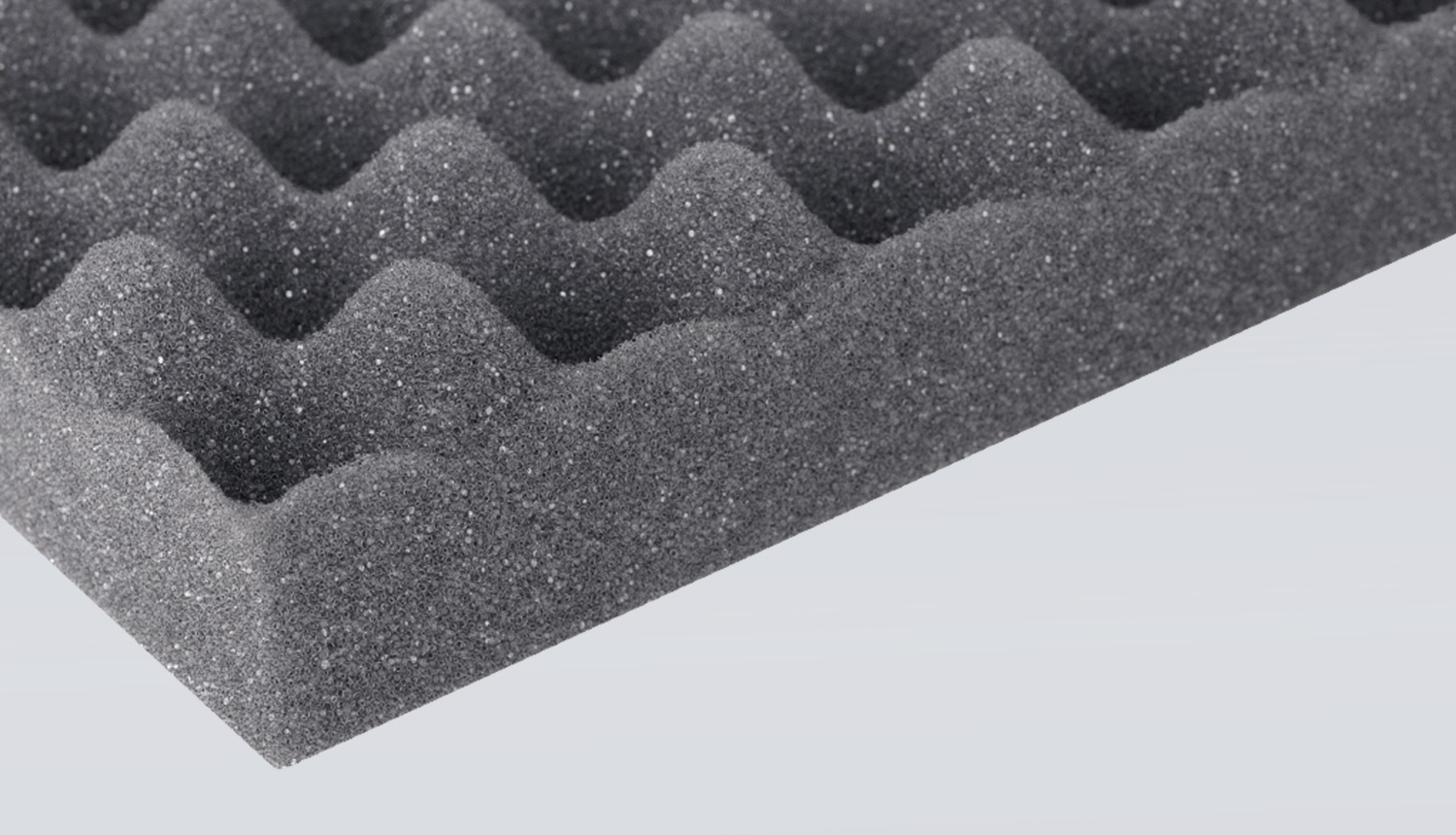

For example nubbly foams or pyramid foams and trapezoidal foams

Frequently asked questions (FAQ)

The foams can be ordered already equipped with a one-sided self-adhesive. With the self-adhesive made of high-quality acrylate, the foam adheres to most surfaces easily and permanently.

The adhesive selection can be found in our online shop.

In individual cases, depending on the installation situation, the weight or the difficult environmental conditions, it may be necessary to fix the foam insulation materials mechanically in addition.

Heavy foils without self-adhesive device are permanently fixed with 2-component polyurethane adhesive from our product range due to their high own weight.

In general, our processing instructions must be observed.

Sound attenuation can be understood as the prevention of sound spreading through the absorption of airborne sound. The sound energy is converted into inaudible oscillation waves during sound absorption and as a result the reflection at a boundary surface is reduced. The acoustics within the room are improved and the noise is reduced.

Basically it can be said that acoustic panels with an irregular structure (waves, pyramids, nubs) "divide" the sound waves a little better and as a result absorb them better. In the medium and high frequency range, good results can be achieved with a thickness of up to 30 mm. For low frequencies we recommend aksutik panels with a thickness of at least 50 mm or our Silphon bass traps.

In the mid to high frequency range, the existing furnishings of the room have a great influence on the reverberation time (sofa, carpet, curtains etc. are also absorbers). The use of additional porous absorbers can be useful in some places, but can also have a (very) fast negative effect and lead to a dull sound without natural dynamics. The upper frequency range is often already damped sufficiently well by the typical living room furnishings even before a planned optimisation of the room acoustics. With any acoustic measures, the main focus should generally be on the lower frequency range. Here a good and sufficient absorption is much more difficult to achieve

By using foam absorbers or foam bass traps, the reverberation time is reduced evenly across the entire frequency spectrum. Thereby a clearer and drier room sound is created. With the targeted use of absorbers, especially the disturbing initial reflections from the walls can be attenuated. The booming bass range can be specifically absorbed by bass straps. The sound image of the room through the use of absorbers becomes more homogeneous, softer and more lively.

The positioning of the acoustic elements on the wall and ceiling can be determined by using a mirror. Viewed from the listening position, the mirror is thereby shifted to the ceiling or wall until the speakers are visible in it. This is the perfect position for the most important acoustic elements.

The Silphon bass traps are most effective when positioned in the corners of a room, because of the sound reflection from the ceiling, walls and floor. In principle you start

with the lineup behind the boxes. The siphon bass traps can be stacked until the desired absorption is achieved.

Booming bass frequencies are often the cause of resonances of sound in the room. Silhouette bass traps effectively suppress the low frequencies and can contribute to an improvement and stop the annoying booming.

Various factors can influence the room acoustics. For example, organic materials such as cork floors, wooden parquet, wooden ceilings or wooden walls are very well suited for pleasant room acoustics. Smooth concrete walls, granite floors and glass surfaces reflect sound very strongly and as a result are acoustically unfavourable.

The interior design has a great influence on the sound spreading and as a result on the sound image in the room. A lounge seating area or a fitted carpet has an absorbing effect and a book shelf on the wall ensures that the sound is diffused. However, a specific improvement of the room acoustics can only be achieved by combining special Silphon acoustic modules.

Materials such as concrete, glass or tiles are placed under sound-reflecting surfaces, which reflect the sound waves up to 100% and as a result do not insulate or absorb the sound. To reduce the volume (sound pressure) and the reverberation time in hard rooms, hard surfaces must be reduced and replaced by surfaces with sound absorbers that absorb the sound.

The sound absorbers allow the sound waves to penetrate the structure and as a result the sound energy is converted into heat or kinetic energy.

In general, it can be said that the more surface of walls and ceiling is covered with foam materials, the less sound can be reflected from them.

From experience, it can be assumed that approx. 40% - 50% of the ceiling and wall surfaces should be covered.

With 100% cladding there is no more natural sound and this leads to unpleasant acoustics.

In general, the thicker the foam, the better and more efficient the sound absorption.

If mainly middle or higher frequencies have to be optimized, good results can be achieved already from a thickness of about 30 mm.

If low frequencies (bass tones) are involved, thicknesses from approx. 50 mm are advantageous. In general, it should be noted that the lower the frequencies and the higher the room, the thicker the foam panels should be.

If a material is too thin, it only absorbs treble. If the material is thicker, it also absorbs low frequencies

Basically, neither pyramid foams nor nubbed foams are suitable for sound insulation to the outside. These two sound insulation materials mainly reduce noise or reverberation in rooms and are used to absorb sound. Above all, the room acoustics are improved. The nubbly foam as well as our pyramid foam are produced "swiss made" in the Vibraplast AG. The pyramids are produced by cross-cutting on a horizontal contour cutting machine, the nubs are produced with a profiling roller. Since the production of pyramid foam takes longer, the price is correspondingly higher than that of nubbed foam. The panel thickness defines which frequencies are absorbed. The thickness of the foam defines which frequencies are absorbed. Thin foam boards tend to absorb in the higher frequency range, while thicker foam boards tend to absorb in the lower frequency range. For the same material thickness, nubbed and pyramid foams are equivalent. It is up to you to decide which look suits which room better.