Tram

Rail vehicles

Tram

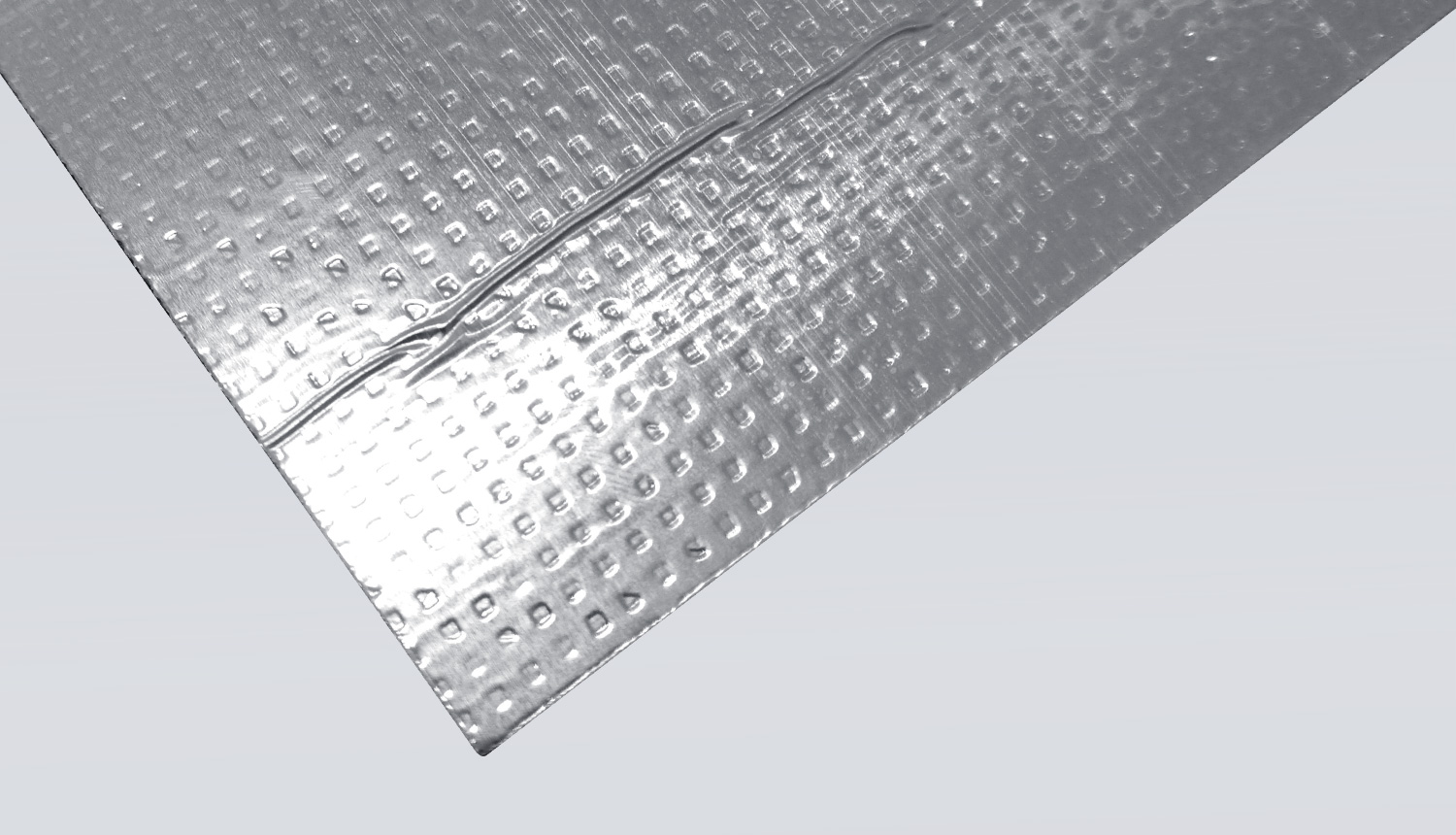

Insulation tram roof area

Noise protection in the tram vehicle roof area.

Insulation tram side wall area

Noise protection in the tram vehicle side wall area.

Insulation tram-floor area

Noise protection in the tram vehicle floor area.

Rubber-metal and spring elements

Vibration insulation components for tram production.

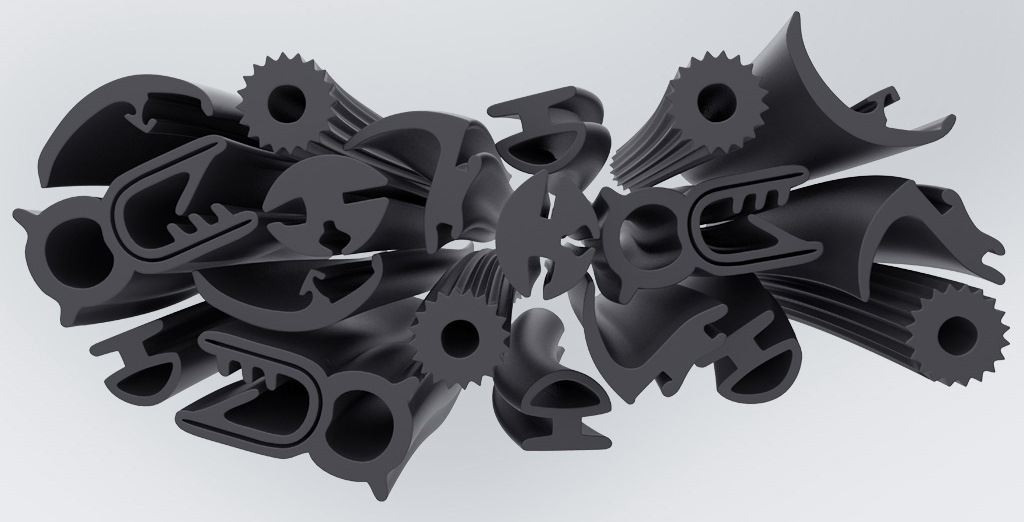

Rubber - Profiles Seals Moulded parts

Rubber products with fire protection standards.

Plastic injection moulded parts

Individual plastic injection moulded parts for the production of trams.

Frequently asked questions (FAQ)

EN 45545 is a material testing standard that has been defining the fire protection requirements of all materials used in rail vehicles uniformly throughout Europe since April 2016.

With the introduction of EN 45545 there will be a transition period during which the previous national standards for fire protection in rail vehicles (e.g. DIN 5510, NF F-16101) will remain valid in parallel.

EN 45545-2 is a very strict fire safety standard and tests that will represent the state of the art in large parts of the world.

EN 45545-2 describes the product requirements in different hazard levels (HL = Hazard Level); the latter are used for the classification of fire safety requirements for materials and components.

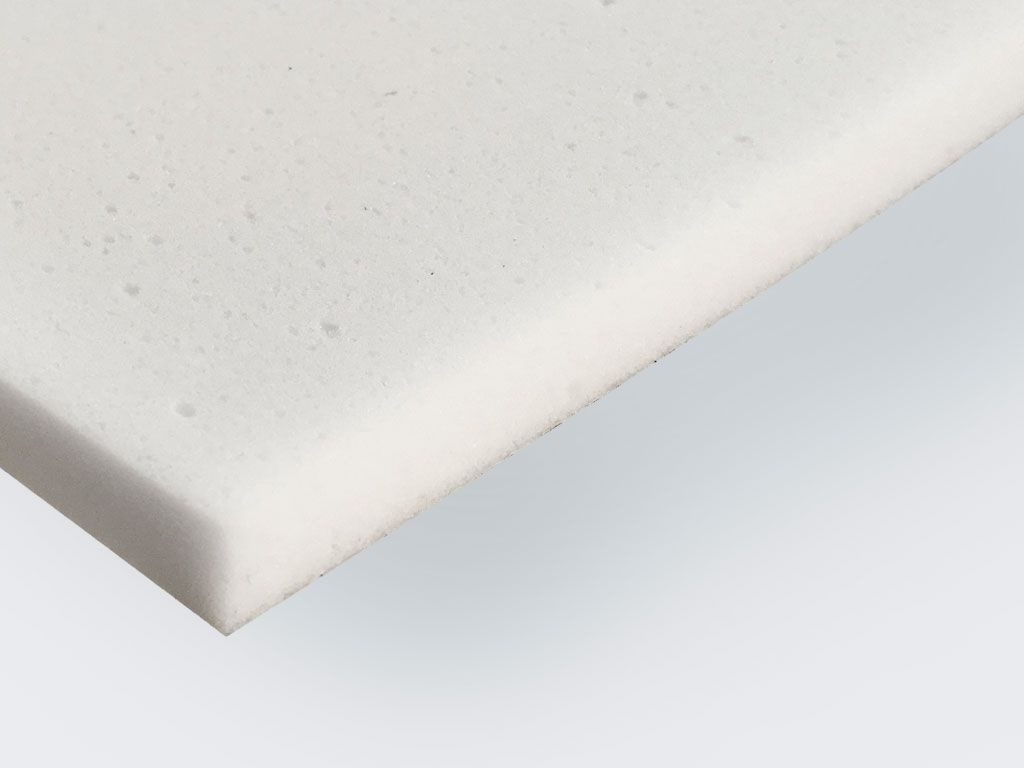

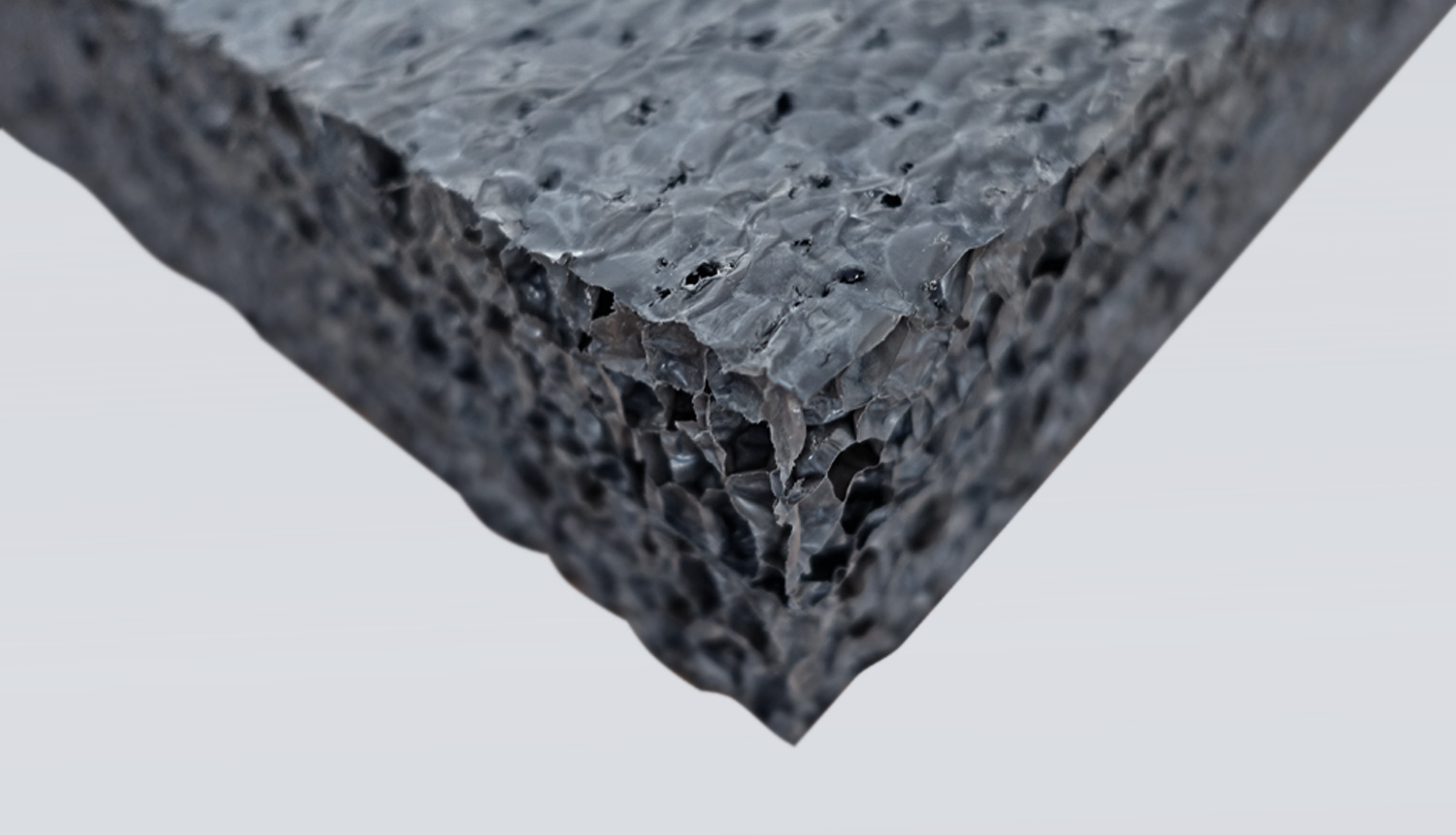

Polyurethane foams (PUR) have an open-pored structure and are therefore used as acoustic foams for sound absorption.

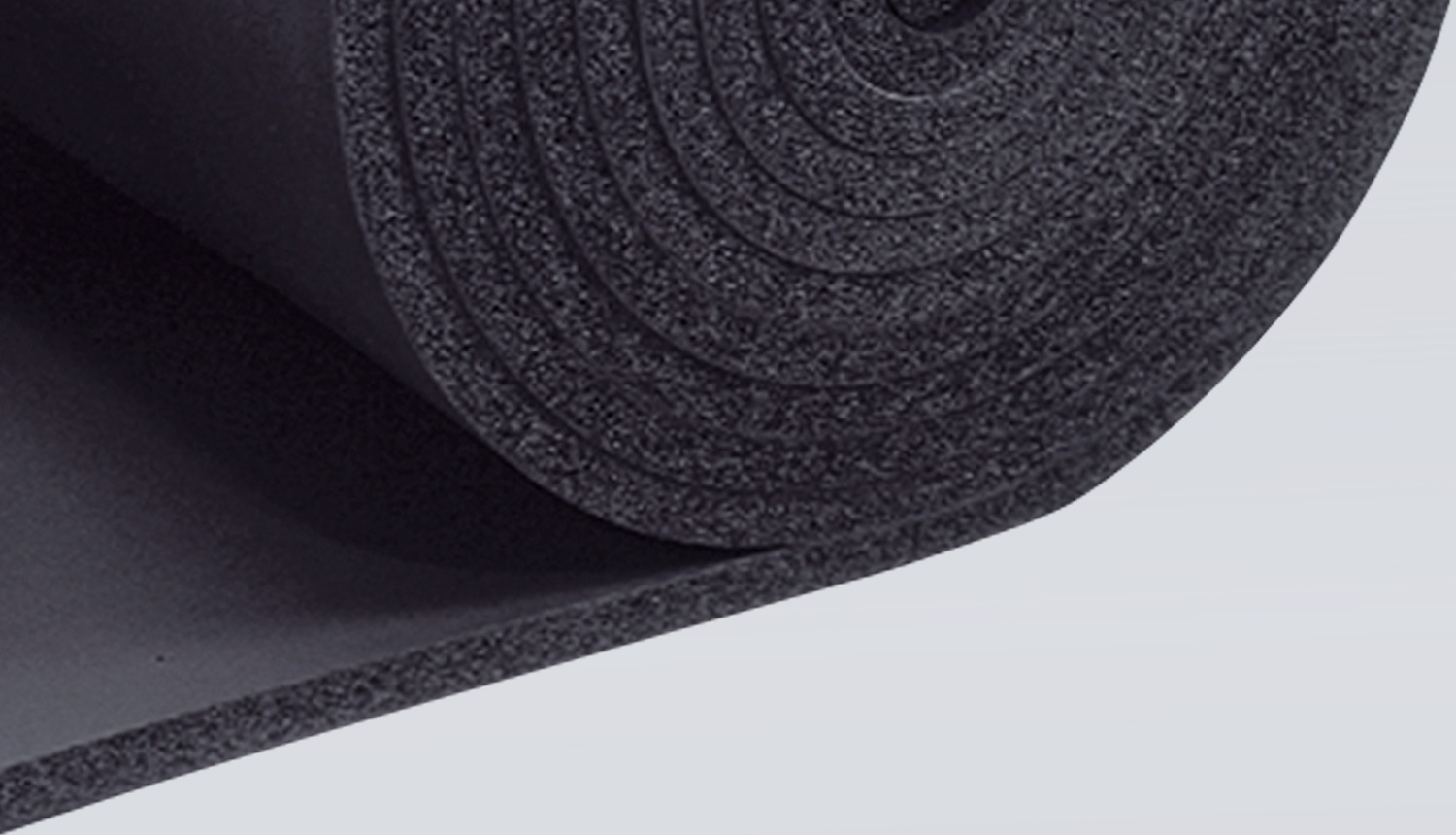

Polyethylene foams (PE) have a closed-cell structure with good thermal insulation properties. PE foams are used for thermal insulation due to their properties and weigh the good compressive strength in the packaging sector.

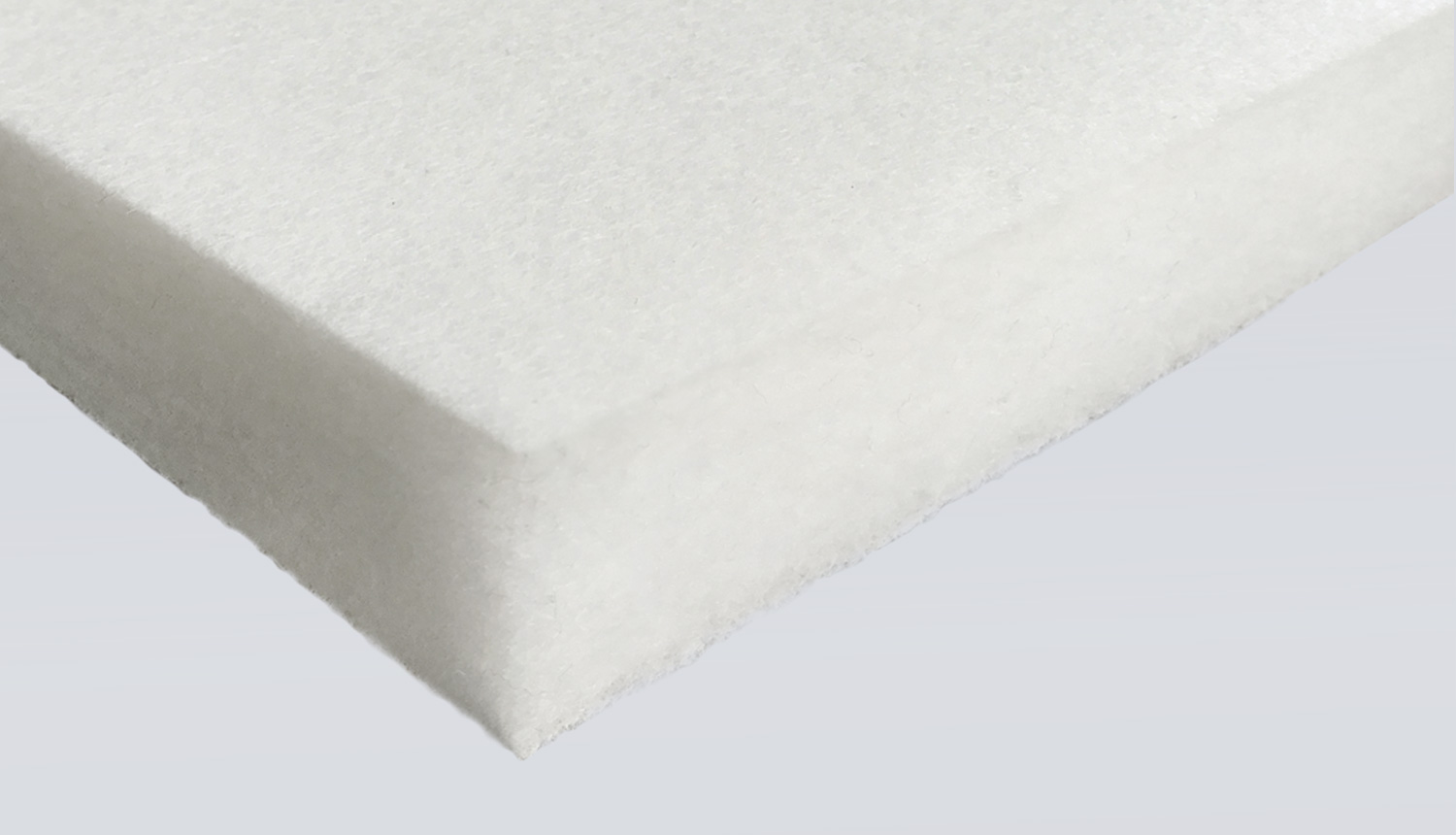

Basotect? melamine foams are open-pored and at the same time provide good thermal insulation and very good sound absorption and also have very good fire protection properties.

This depends on the cross-section, the type of material and various other factors. As a rule of thumb, however, one can assume that rubber is approx. 25 running metres.

This in turn depends on many different factors. For rubber profiles, the prices usually range from CHF 500.00 to 1500.00

It is best to provide as much information as possible! For example, as there are: Material, drawings, samples, sketches of the problem to be solved, required quantity, requirements regarding chemical resistance, temperature range, colour, fire protection regulations, approvals (e.g. food), etc.

We can also supply glued, welded or vulcanised rings and frames, sections to fixed lengths, etc. Even self-adhesive finished profiles are no problem.

Strips of cellular rubber or rubber, flat seals, milled profiles, moulded parts, etc. are often a sensible alternative.

Rubber profiles, especially in contrast to metals, have relatively large permissible dimensional tolerances (ISO 3302-1 E2 or E3 for cellular rubber). The wall thickness is best kept to a minimum of about 0.8 - 1.0 mm. For some rubber qualities, 0.5 mm is also possible, but not thinner. Extruded profiles never have sharp edges, i.e. there is always a certain radius and precise, especially right angles, do not exist. A constructive solution must be found here. For example with a certain suit.