Insulation tram-floor area

Noise protection in the tram vehicle floor area.

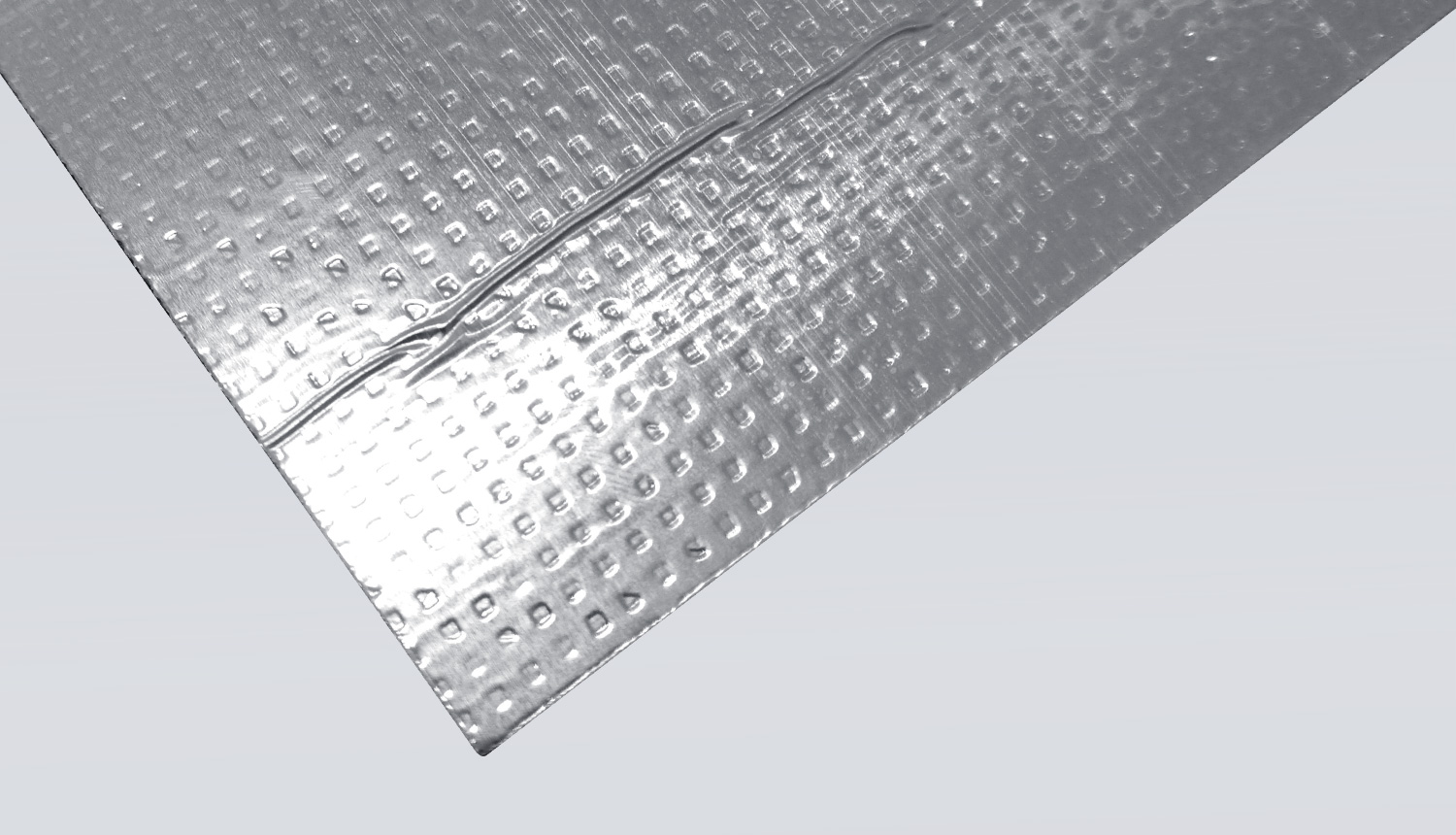

As a reliable supplier of components for the rail vehicle industry for over 50 years, we have been able to establish ourselves as a specialist in the sector of sound and heat insulation, whether for trams, regional trains, high-speed trains or locomotives. We supply acoustically optimised parts for series production, assembled in ready-to-install assembly sets and labelled, which are installed behind wall and ceiling panelling, in the floor area or in the ventilation duct of the rail vehicle. Our rail vehicle products meet the high requirements of the European fire protection standards. The Vibraplast machinery is one of the most modern and efficient foam processing plants and is always kept up to date. With a wide range of production methods we are able to carry out the complete manufacture of the sound insulation products in-house. What is delivered to our factory as a raw foam block only leaves the factory as a fully developed product. Further core competences are noise protection engineering, the recording of actual conditions, as well as the design, calculation and construction of acoustic measures and solutions in the airborne and structure-borne sound range. The design department produces the complete and optimised set of drawings of the insulation for the entire vehicle.?

Frequently asked questions (FAQ)

EN 45545 is a material testing standard that has been defining the fire protection requirements of all materials used in rail vehicles uniformly throughout Europe since April 2016.

With the introduction of EN 45545 there will be a transition period during which the previous national standards for fire protection in rail vehicles (e.g. DIN 5510, NF F-16101) will remain valid in parallel.

EN 45545-2 is a very strict fire safety standard and tests that will represent the state of the art in large parts of the world.

EN 45545-2 describes the product requirements in different hazard levels (HL = Hazard Level); the latter are used for the classification of fire safety requirements for materials and components.

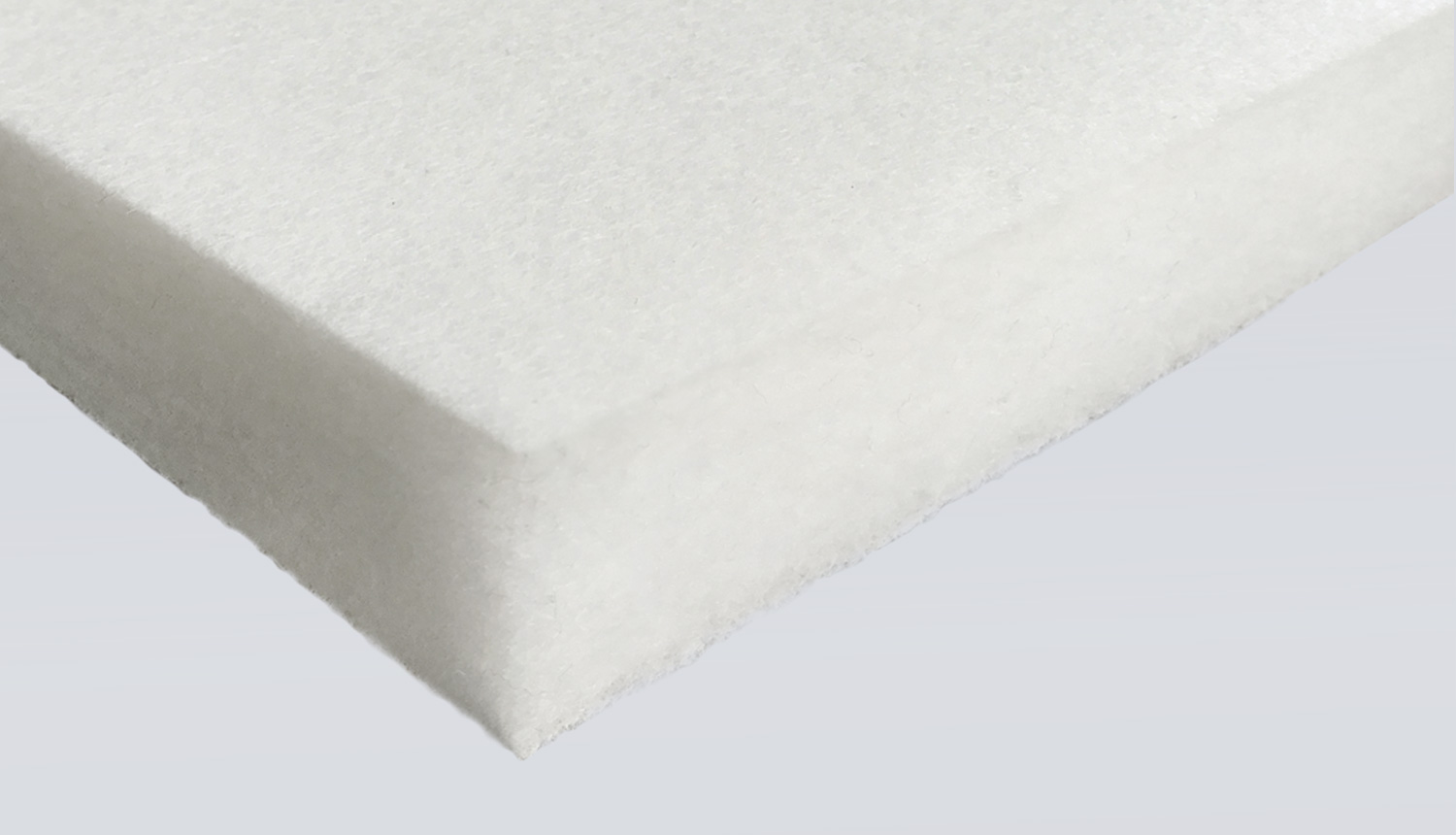

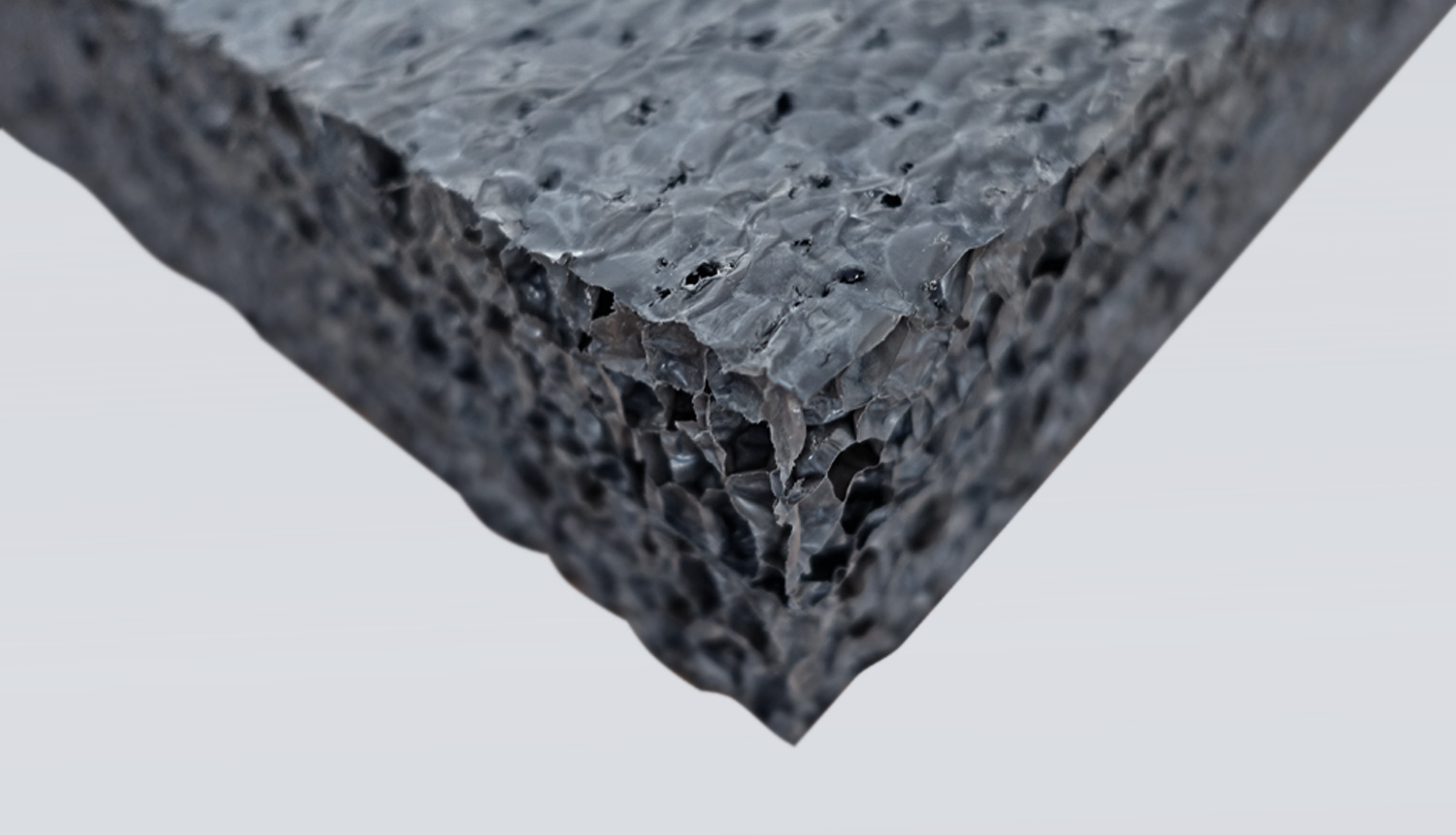

Polyurethane foams (PUR) have an open-pored structure and are therefore used as acoustic foams for sound absorption.

Polyethylene foams (PE) have a closed-cell structure with good thermal insulation properties. PE foams are used for thermal insulation due to their properties and weigh the good compressive strength in the packaging sector.

Basotect? melamine foams are open-pored and at the same time provide good thermal insulation and very good sound absorption and also have very good fire protection properties.