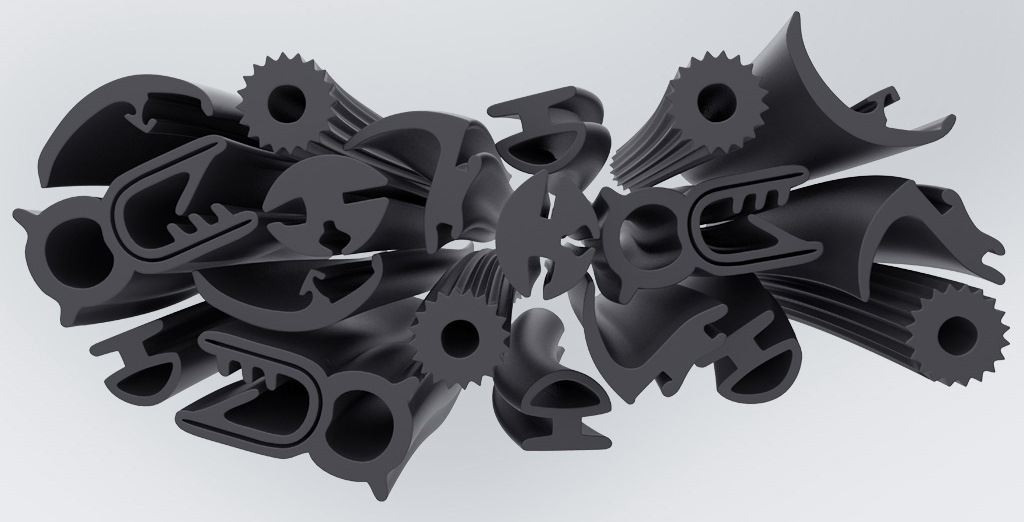

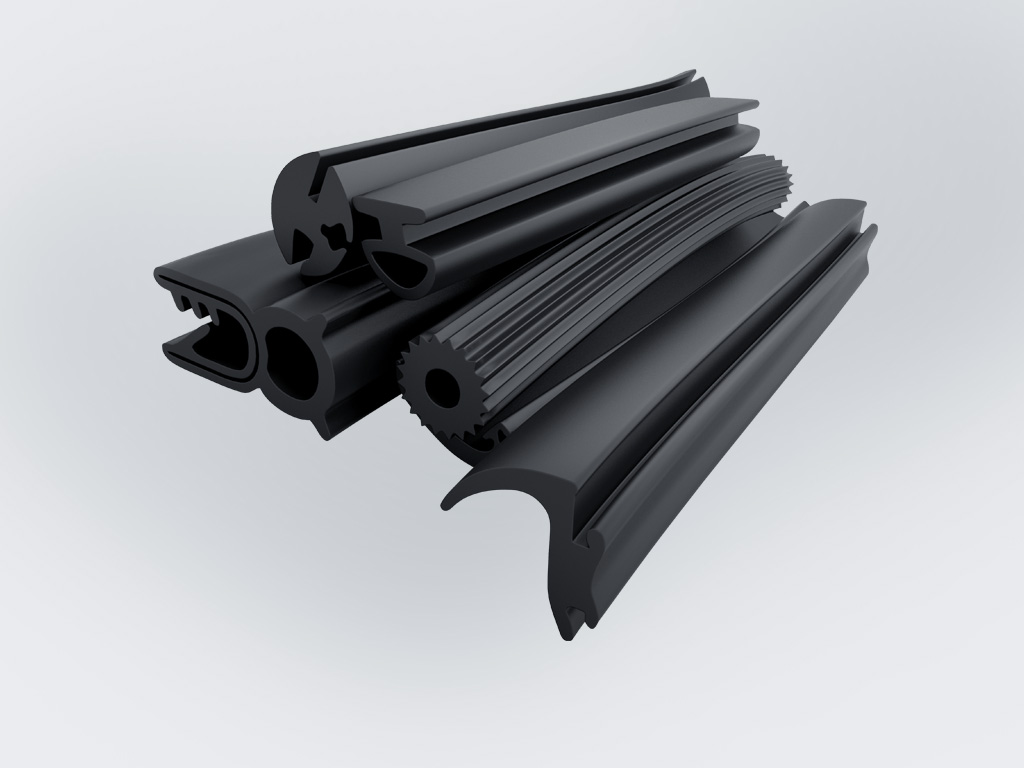

Rubber profiles

Online consulting!

We only produce customer-specific rubber-plastic profile solutions and unfortunately we do not keep standard profiles in stock.

Vibraplast AG offers profile solutions in all rubber (also sponge rubber) and many plastic qualities.

Of course, we are also able to work constructively for you to develop a solution for your specific problem.

What does a profile tool cost?

For rubber profiles, the price range is between CHF 500 and 1500, depending on size and complexity.

Plastic profiles (thermoplastics with the exception of TPE) are considerably more expensive.

What is the minimum purchase?

Depending on the cross-section and the type of material, the rule of thumb for the minimum purchase of rubber profiles is approx. 25 running metres.

For plastic profiles the minimum quantity is considerably higher.

What information do we need to produce a profile?

It is best to provide as much information as possible. For example: material quality, Shore hardness, drawings, samples, sketches of the problem to be solved, required quantity, requirements regarding chemical resistance, temperature application range, colour, fire protection regulations, approvals (e.g. food), ecc.

A profile is always delivered in rolls only?

No. We can also supply glued, welded or vulcanised rings and frames, sections to fixed lengths, etc. In addition, profiles can also be self-adhesive.

Are there alternatives to extruded profiles?

Strips of cellular rubber or rubber, flat gaskets, milled profiles (plastic), moulded parts, etc. are often a reasonable alternative.

What about the tolerances of rubber profiles?

Rubber profiles, especially in contrast to metals, have relatively large permissible dimensional tolerances (ISO 3302-1 E2 or E3 for cellular rubber). It is best to keep wall thicknesses to a minimum of about 0.8 -1 mm. With some elastomers, 0.5 mm is also possible, but not thinner. Extruded profiles never have sharp edges, i.e. there is always a certain radius and precise, especially right angles, do not exist. A constructive solution must be found here. For example with a certain suit.

You can find more information here!

Frequently asked questions (FAQ)

We only produce customer-specific rubber-plastic profile solutions and unfortunately we do not keep standard profiles in stock.

Vibraplast AG offers profile solutions in all rubber (also sponge rubber) and many plastic qualities.

Of course, we are also able to work constructively for you to develop a solution for your specific problem.

What does a profile tool cost?

For rubber profiles, the price range is from CHF 500 to 1500, depending on size and complexity.

Plastic profiles (thermoplastics with the exception of TPE) are considerably more expensive.

What is the minimum purchase?

Depending on the cross-section and the type of material, the rule of thumb for the minimum purchase of rubber profiles is approx. 25 running metres.

For plastic profiles the minimum quantity is considerably higher.

What information do we need to create a profile?

Preferably as much information as possible. For example: material quality, Shore hardness, drawings, samples, sketches of the problem to be solved, required quantity, requirements regarding chemical resistance, temperature application range, colour, fire protection regulations, approvals (e.g. food), ecc.

A profile is always delivered in rolls only?

No. We can also supply glued, welded or vulcanised rings and frames, sections to fixed lengths, etc. In addition, profiles can also be self-adhesive.

Are there alternatives to extruded profiles?

Strips of cellular rubber or rubber, flat gaskets, milled profiles (plastic), moulded parts, etc. are often a sensible alternative.

What about the tolerances of rubber profiles?

Rubber profiles, especially in contrast to metals, have relatively large permissible dimensional tolerances (ISO 3302-1 E2 or E3 for cellular rubber). It is best to keep wall thicknesses to a minimum of about 0.8 -1 mm. With some elastomers, 0.5 mm is also possible, but not thinner. Extruded profiles never have sharp edges, i.e. there is always a certain radius and precise, especially right angles, do not exist. A constructive solution must be found here. For example with a certain suit.

It is best to provide as much information as possible! For example, as there are: Material, drawings, samples, sketches of the problem to be solved, required quantity, requirements regarding chemical resistance, temperature range, colour, fire protection regulations, approvals (e.g. food), etc.

This depends on the cross-section, the type of material and various other factors. As a rule of thumb, however, one can assume that rubber is approx. 25 running metres.

This in turn depends on many different factors. For rubber profiles, the prices usually range from CHF 500.00 to 1500.00

Rubber profiles, especially in contrast to metals, have relatively large permissible dimensional tolerances (ISO 3302-1 E2 or E3 for cellular rubber). The wall thickness is best kept to a minimum of about 0.8 - 1.0 mm. For some rubber qualities, 0.5 mm is also possible, but not thinner. Extruded profiles never have sharp edges, i.e. there is always a certain radius and precise, especially right angles, do not exist. A constructive solution must be found here. For example with a certain suit.

We can also supply glued, welded or vulcanised rings and frames, sections to fixed lengths, etc. Even self-adhesive finished profiles are no problem.

Strips of cellular rubber or rubber, flat seals, milled profiles, moulded parts, etc. are often a sensible alternative.

We will be pleased to cut to the desired dimension according to your individual specifications.

The compression of our edge protection sealing profiles should be a maximum of 50%, because

otherwise the tightness as well as the restoring forces are impaired. In practice

the profiles are compressed between 30-40%.

Neoprene is a brand of the DuPont company and is a CR chloroprene synthetic rubber. The abbreviation of chloroprene rubber is CR. Vibraplast AG has no CR neoprene in its product range but a comparable commercial CR rubber with similar quality characteristics. Consult our technical data sheet in our online shop and compare the properties of our CR rubber quality.

The FDA (Food and Drug Administration), is an American supervisory authority, which is responsible for the control of all goods placed on the market in the USA. This includes all imports into the USA, therefore the regulations of the FDA authority are also important for European manufacturers. These regulations are binding for exporters to the USA.

The FDA sets extremely strict requirements in the food sector where a large number of rubber and plastic products are used and as a result come into contact with food or drinking water. The materials must not release any ingredients into the food. As a result, all plastics that come into contact with food should be FDA-compliant.

Silicone rubbers have the highest reliability and outstanding properties among elastomers. Silicone rubbers can be used even in the most adverse conditions and can be stored for long periods of time without compromising their properties. The unique silicone rubber surpasses conventional rubber qualities in many respects. Thanks to the excellent properties of silicone rubber, it is used in many applications where a conventional rubber grade would not work.

Different types of adhesive can be used for bonding rubber. The choice of the right adhesive for rubber depends on the mixture of the respective rubber, therefore it is advisable to test it on a small area before gluing the rubber over the entire surface.

In our online shop page https://www.vibraplast.ch/de/gummi-kunststofftechnik/Klebstoffe you will find a range of superglues for gluing rubber to each other or for bonding with different material combinations. The following elastomers/rubbers have proven to be suitable for bonding with superglue:

EPDM (ethylene-propylene-diene rubber)

NR (natural rubber)

CR (Cloroprene rubber neoprene)

IIR (isobutylene-isoprene rubber)

SBR (styrene-butadiene rubber)

NBR (nitrile butadiene rubber)

Rubber bondings with superglue have the advantage that it hardens in a few seconds and the adhesive bond can be loaded immediately.

The following advice for bonding rubber should be observed:

clean surface

no double-sided adhesive application

a glueing gap as thin as possible

in the case of mitre-cut gluing or butt gluing, ensure a straight, smooth and fresh cut

skin contact should be avoided if possible, wear latex gloves if possible

Food grade rubber/elastomer is safe to use with food and meets the requirements of the FDA, Food Standards Agency. Food grade elastomer is non-toxic and does not discolor or alter the food with which it comes into contact. Food grade rubber qualities can be used safely in the production of food and beverages.

Rubber bellows are similar to an accordion, folded hoses. They are mainly used to protect machine parts from general soiling, weather influences, dust, etc. and at the same time seal against their environment. Elastomers (rubber) are the most common material used for bellows because of their safety, elasticity and long service life.

Bellows from Vibraplast AG are only manufactured according to customer drawings. Vibraplast AG has no standard range of bellows.

For the production of bellows, a vulcanization tool is required, which can be delivered from approx. 800 and with a delivery time of approx. 6 weeks, depending on the bellows size. We would be pleased to advise you on the individual design of your bellows.

KTW stands for "plastic drinking water". Specifically, this guideline refers to the requirements for the material to be approved as such.

This KTW regulation is intended to ensure that neither materials nor materials used in drinking water supply, such as seals or drinking water hoses, release undesirable substances into the drinking water by leaching. Secondly, it should be prevented that the products or materials used promote the growth of microorganisms such as algae or bacteria.

Hardness testing of elastomers (rubber)

The hardness test of elastomers (rubber) which is most commonly used is the Shore hardness test according to DIN ISO 7619-1.

The Shore hardness is the resistance of a rubber sample to the penetration of a conical body of certain dimensions under a defined compressive force. Depending on the design of the measuring body, a distinction is made between Shore A for softer elastomer compounds and Shore D for harder elastomer compounds.

For a perfect measurement of Shore hardness, the standard specifies a sample thickness of 6.0 mm. If measurements are carried out on finished products with smaller wall thicknesses, they usually lead to incorrect results.

Commercially available elastomer compounds for technical rubber mouldings have a hardness range of 20-90 Shore A