Interior noise protection

Motorboats

Interior noise protection

Acoustic optimizations in the motorboat interior.

What bothers a motorboat enthusiast most about their hobby, thereby the answer is often: the engine noise. There are, however, various measures to reduce the annoying noise.?

Soundproofing and soundproofing materials applied to bulkheads and engine room ceilings eliminate the unwanted noise emissions.

So if you want to ensure more "quiet on board" or if you have had enough of the old, crumbly sound insulation, there is something you can do. First a few basics concerning the different types of sound, a distinction is made between the groups airborne sound and structure-borne sound. The former is medium to high frequency and spreads through the medium air. This can be reduced with the help of sound insulation panels which are attached to the bulkheads of the engine compartment.?

The structure-borne sound, on the other hand, is transmitted via solid bodies.

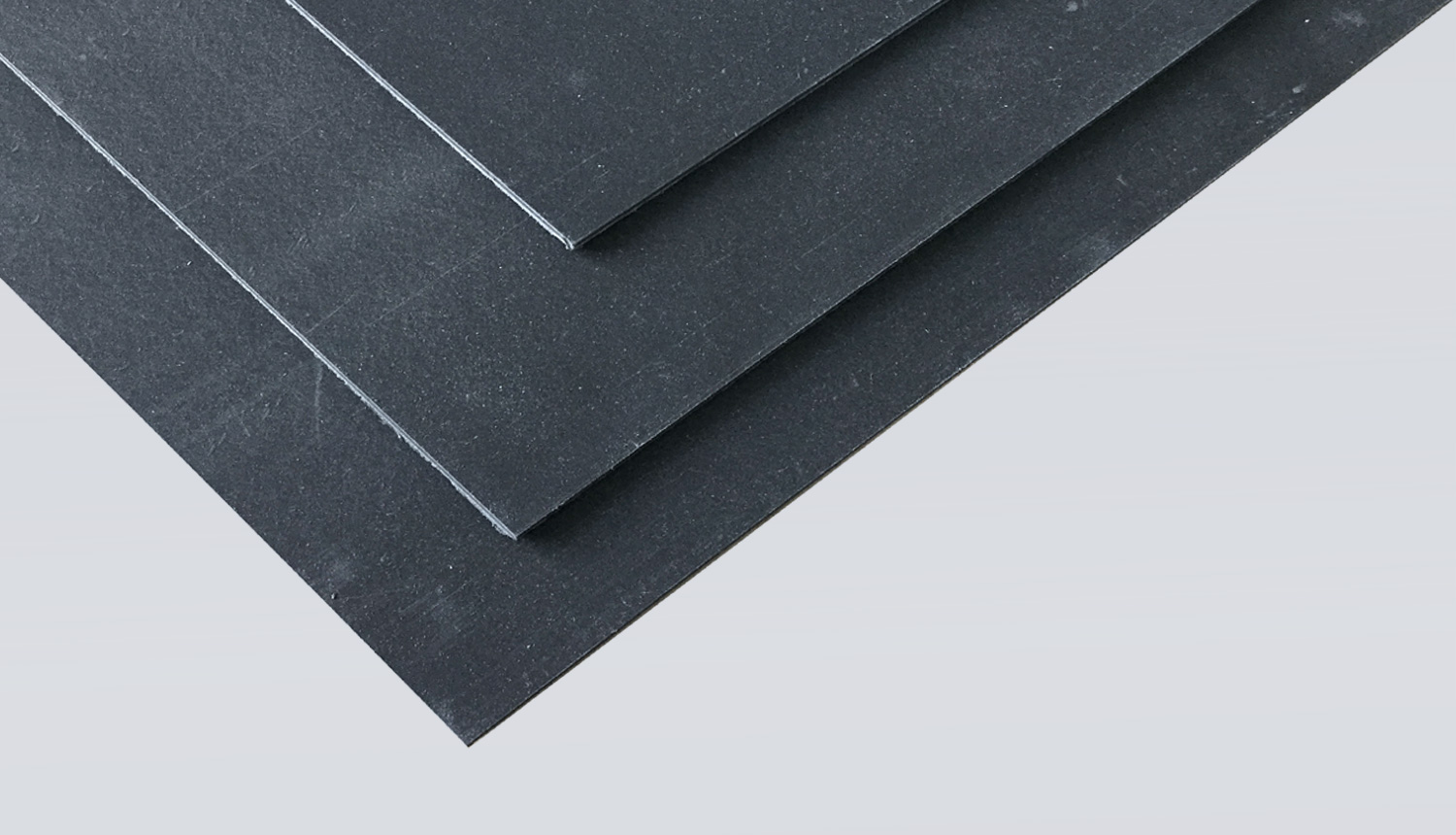

In the case of the engine, for example, it is the vibrations that reach the hull of the boat via the foundation. This rather low-frequency noise of the engine can only be minimized by the best possible mass compensation and a perfectly adapted engine mount from our vibration insulation range. In order to prevent structure-borne noise from spreading throughout the entire boat, Teroform heavy foils should be used, which can contain the structure-borne noise due to their high mass. Various effects come into play in sound insulation. For example, sound waves that hit a bulkhead are reflected on the one hand and absorbed on the other. Another part also penetrates the walls of the engine compartment and is sometimes perceived by us as a disturbing noise. As a result the nature of the barrier layer is an important factor in how many sound waves and in what strength reach the inside of the boat.

Whether you want to line the ship's engine room, the interior or the floor in the interior - the procedure is the same for all variants.

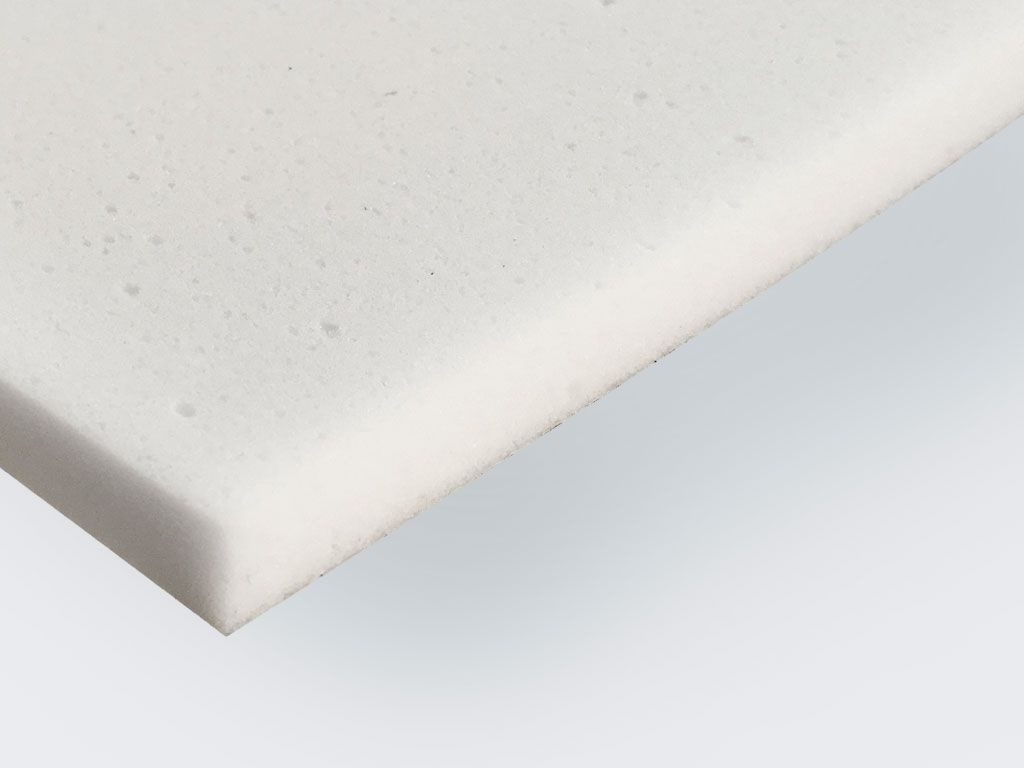

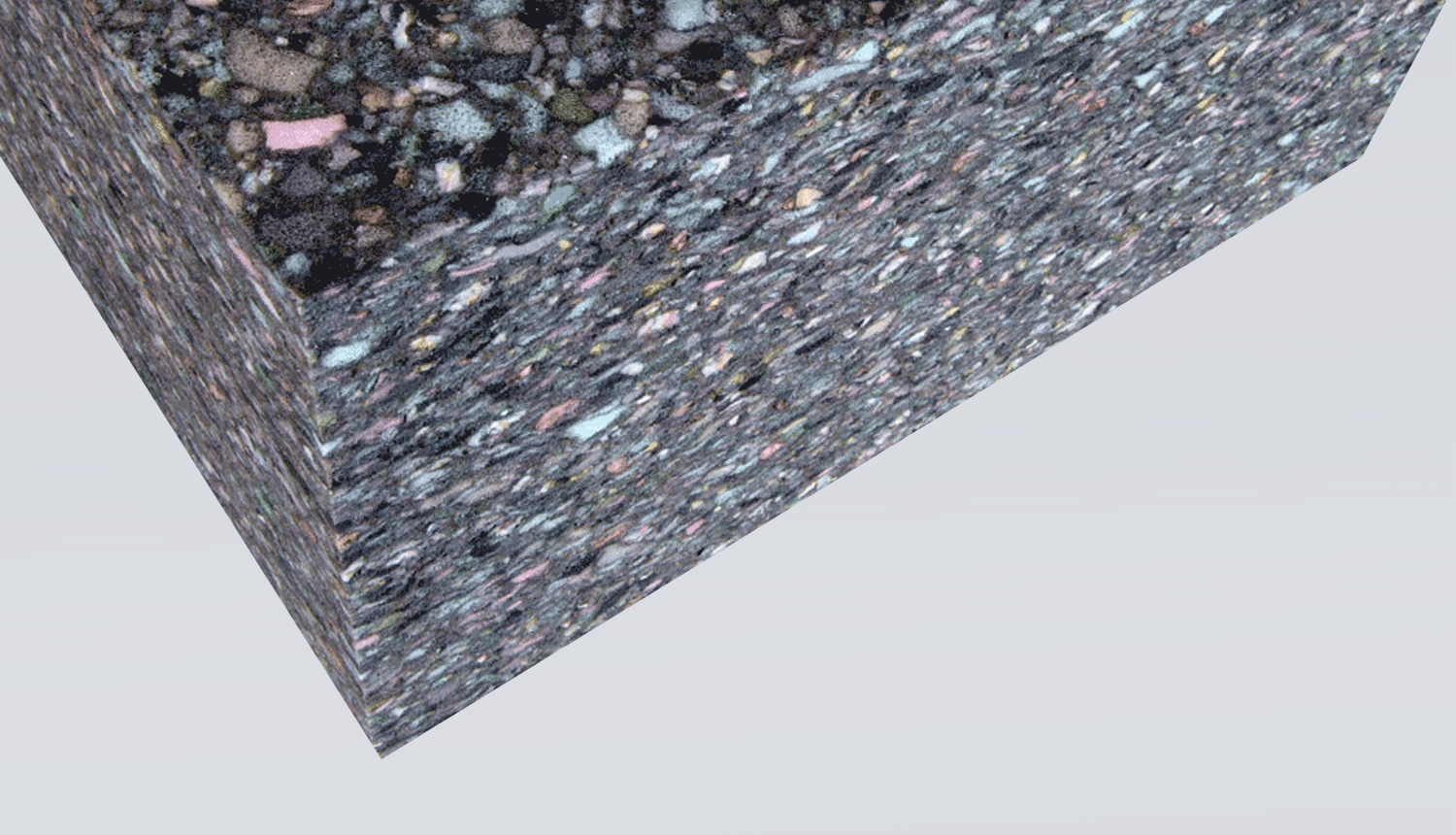

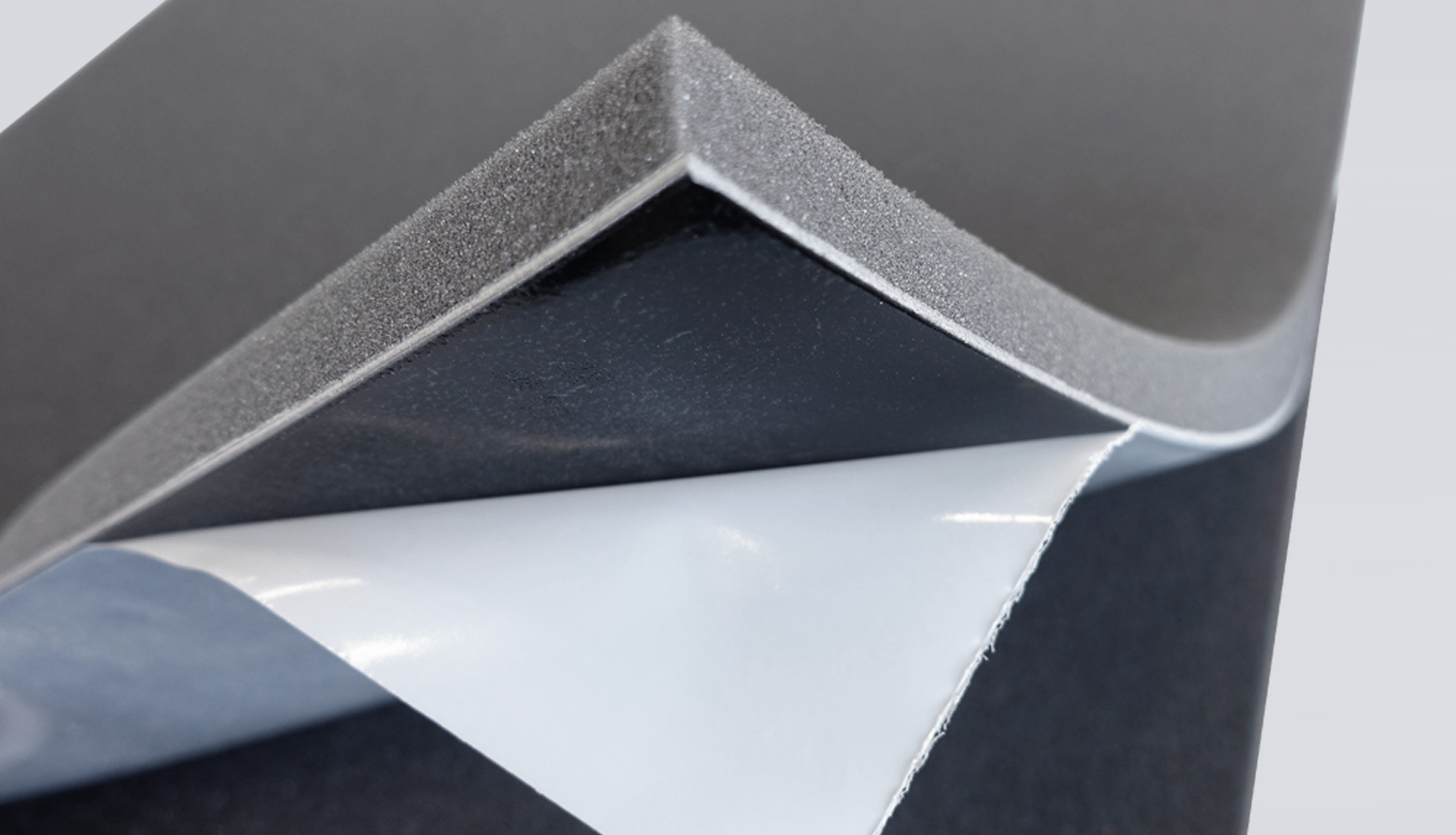

In the boat area these rooms are insulated with foam. The best way to do this is to use our flame-resistant PUR recycled foam in combination with a Teroform? plastic damping foil or a Terodem? bitumen heavy-duty foil. The plastic or bituminous heavy foil is approx. 2 mm thick and on the one hand, deadened metal surfaces (reduces vibrations) and insulates noise. The composite foam bonded to it additionally reduces reverberation and noise.

If you are insulating the engine compartment, glue the flame-resistant, recycled foam onto the first Terodem? bitumen laid - the thicker, the better the insulation. For airborne sound absorption and as thermal insulation, our Vibra? glass-fibre matting for thermal acoustic insulation is also suitable for the engine compartment. If the foam could get wet, our skinned flat foams with PU skin Silphon?and water-repellent melamine foams Hydrophob Basotect? G+ / UF can also be laminated with the heavy foil.?