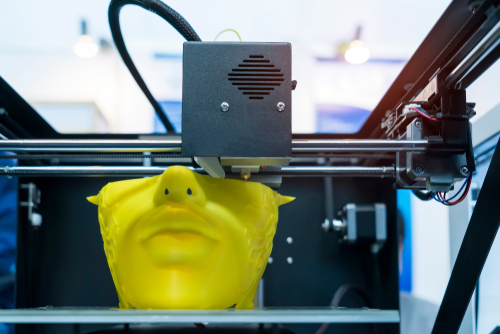

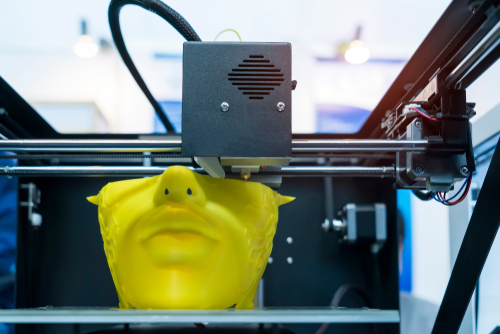

CONSTRUCTION TIPS FOR THE CORRECT WALL THICKNESS OF 3D PRESSURE PARTS

The importance of the correct design of wall thicknesses for the success of 3D printing cannot be overestimated. That is why we have compiled the most important information and tips for the construction of wall thicknesses of 3D printed parts for you here.

The minimum possible wall thickness depends especially on the chosen material. Nevertheless, the following rule of thumb applies to all 3D printed parts: The harder the material, the smaller the minimum wall thickness. With many additive manufacturing processes this is 0.8 mm.

The correct minimum wall thickness for 3D models

The most common plastic materials have a minimum wall thickness of 0.7 - 1.0 mm. With even lower minimum values of up to 0.3 mm you can design your 3D models using metal powders. We will be pleased to provide you with an overview of the different minimum wall thicknesses according to materials and the additive manufacturing technologies used.

Minimum wall thicknesses for plastic materials in Selective Laser Sintering (SLS) and Fused Deposition Modeling (FDM)

For Selective Laser Sintering (SLS) you can use PA 2200, PA-GF or PP plastic with a wall thickness of 0.7 mm. The same wall thickness can also be used for Fusion Desposition Modeling if you are working with PLA plastic. Other SLS and FDA plastic types such as PA-FR, Alumide, TPU 92A, ABS plastic, ULTEM or PC polycarbonate require a minimum wall thickness of one millimeter.

Minimum wall thicknesses for plastic materials in stereolithography (SLA)Also in stereolithography (SLA) the material used is plastic, so you should design your 3D models with a wall thickness of at least 0.8 mm.

Minimum wall thicknesses for plastic materials with PolyjetWhen manufacturing 3D printed parts with the PolyJet process, use materials with a minimum wall thickness of 0.8 mm with plastics such as VeroWhitePlus.

Minimum wall thicknesses for 3D printed metal parts with selective laser melting (SLM)

The SS 420 material mix of stainless steel, copper and tin with a minimum wall thickness of 0.3 mm is currently the material that can be designed with the lowest wall thickness using the EBM process and is one of the most cost-effective materials for SLM in comparison with the following metal materials The other metals used in SLM have the following properties:

- Aluminium can be processed with a minimum wall thickness of 0.5 mm - stainless steel 316L or 1.4404 with a minimum wall thickness of 0.5 mm - titanium with a minimum wall thickness of 0.5 mm - brass with a minimum wall thickness of 0.6 mm - bronze with a minimum wall thickness of 0.8 mm - copper with a minimum wall thickness of 0.8 mm - Inconel and titanium with a minimum wall thickness of 0.5 mm

Further factors for a stable 3D construction

In addition to the correct wall thickness of your 3D model, you should also consider other factors in your design so that the model can be printed. To plan your 3D print file correctly, you should follow these tips:

- all models must be "waterproof", i.e. completely closed - the printed part should not have any open areas or edges - the model must have a high number of polygons for a smooth surface - the 3D surface object should be defined as a triangular or square mesh - the partial bodies must be completely closed and can be "plugged" into the model

Did these tips help you? If your answer is: "Yes, but...", you can rest assured. Because we have even more tips on how to correctly create and order 3D printed parts.

Just click here and look for your answer in the FAQ about the design and 3D printing of models.