Simply put, additive manufacturing is the more technical term for 3D printing, which is mainly used in industry. The technology of additive manufacturing means a build-up or layered manufacturing of parts. This means no formative or subtractive manufacturing of parts such as milling, grinding or turning. In this article you will learn why additive manufacturing and 3D printing are not quite the same thing and what rapid prototyping and direct digital manufacturing have in common with additive manufacturing.

How does additive manufacturing technology work?

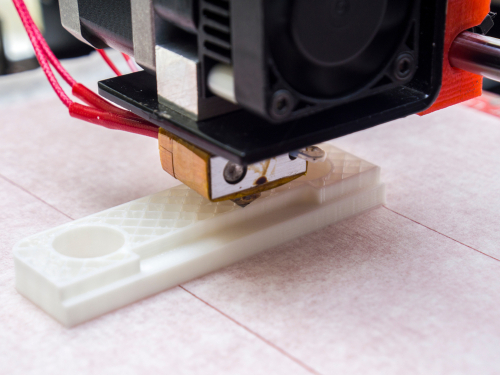

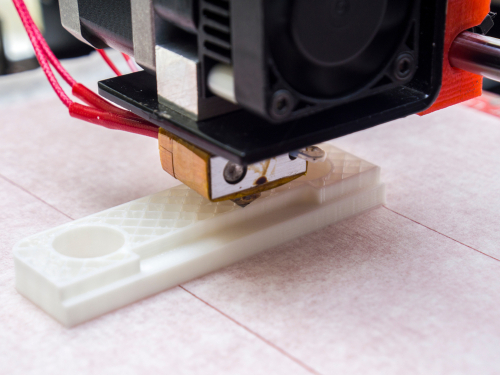

The basic idea of additive manufacturing is to add material step by step instead of removing it. Parts made of different materials are created by adding thousands of tiny layers that combine to form an object. The process involves the use of a computer and special 3D CAD software that can send messages to the printer to "print" the desired shapes. According to the input of the CAD plan and the computer, the individual object is then printed layer by layer using the appropriate machines and materials. These layers are wafer-thin and can thereby be printed repeatedly on top of each other and fused together during the process until the form is finished. What are the advantages of additive manufacturing compared to traditional manufacturing processes? Probably the greatest advantage of additive manufacturing is the high flexibility in production. You can produce more complex shapes than with classic manufacturing processes, such as milling. The manufacturing process also often allows you to dispense with supports, frame construction or thicker wall widths, as the form can be produced seamlessly, so to speak, and as a result is much more stable. However, there are countless other advantages of additive manufacturing, thereby

- 3D pressure parts can be hollowed out, which saves material and costs - other materials become available that better meet your requirements for density, resistance or flexibility - CAD planning and rapid prototyping can be used to plan and manufacture your objects more quickly

The different types and related technologies of additive manufacturing briefly explained:

When entering 3D printing technology and additive manufacturing, terms such as 3D printing, rapid prototyping and DDM are often tossed around. We would be happy to explain them to you.

3D Printing Basically it can be said that 3D printing describes the same manufacturing process - but from different perspectives. The term additive manufacturing focuses on the different manufacturing processes; subtractive manufacturing, formative manufacturing and additive manufacturing (read more about this here). 3D printing is often considered as a single process step in 3 dimensional manufacturing, from 3D scanning to 3D printing.

Rapid PrototypingRapid Prototyping describes the rapid production of a model or prototype using CAD software for design and 3D printers for manufacturing, allowing you as a mechanical engineer, engineer or designer to make multiple changes to your design quickly and efficiently before producing the model in a large volume.

Direct Digital Manufacturing (DDM)Direct Digital Manufacturing describes the process of printing an object directly from a CAD document. DDM uses additive manufacturing technologies to implement this process. As a result, DDM describes the process of how additive manufacturing is used in the production of objects.

Additive manufacturing explained in one sentence

Finally, it can be summarized that there are many different perspectives and many related terms in additive manufacturing. However, all of them point to the core of additive manufacturing: "The additive manufacturing method makes it possible to produce complex parts from a wide variety of materials, based on CAD data, in a simple and quick way.

To the 3D Print online shop, test us!